Application :

Recommended for use in Steel Mills, Thermal Plants, Oil Mills, Fertilizer Plants, Petroleum Refinery, for conveying saturated steam at a specified steam pressure.

Lining :

Steam and Heat Resistant rubbber compound.

Reinforcement :

GS 1: One High Tensile Steel Wire braid. GS 2: Two high Tensile Steel Wire braids.

Cover :

EPDM Rubber Resistant to Heat, Abraisen, Ozone and Weather.

Temp Range:

Up to +170oc

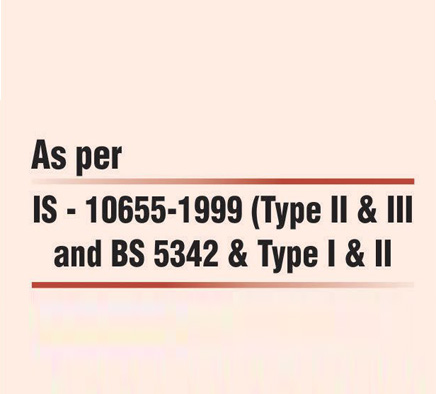

Standard :

Our Product meet Indian and Global Standards.

Branding :

GS 1: Ganga SPEEDLINE Steam Hose DN...-...."“W.P.10 BAR / 150 PSI”

GS 2: Ganga SPEEDLINE Steam Hose DN...-...."“W.P.16 BAR / 232 PSI”

Colour :

Inner & Outer Black